This gearmotor is a powerful 24V brushed DC motor with a 18.75:1 metal gearbox and an integrated quadrature encoder that provides a resolution of 64 counts per revolution of the motor shaft, which corresponds to 1200 counts per revolution of the gearbox’s output shaft. The gearbox is composed mainly of spur gears, but it features helical gears for the first stage for reduced noise and improved efficiency. These units have a 16 mm-long, 6 mm-diameter D-shaped output shaft. This gearmotor is also available without an encoder.

Key specifications:

| voltage | no-load performance | stall extrapolation |

|---|

| 24 V |

530 RPM, 100 mA |

9.5 kg⋅cm (130 oz⋅in), 3 A |

Measuring 37 mm (1.46″) in diameter, these brushed DC gearmotors are the largest and most powerful we carry. They are available in a range of gear ratios from 6.3:1 to 150:1 and with 12 V or 24 V motors, and all versions are available with integrated 64 CPR quadrature encoders on the motor shafts. The 12 V and 24 V motors offer approximately the same performance at their respective nominal voltages, with the 24 V motor drawing half the current of the 12 V motor. See the 37D metal gearmotor datasheet (2MB pdf) for more information, including detailed performance graphs for each gearmotor version. You can also use our dynamically sortable 37D gearmotor comparison table to search for the version that offers the best combination of speed, torque, and current draw for your particular application.

In general, these kinds of motors can run at voltages above and below the nominal voltages; lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor.

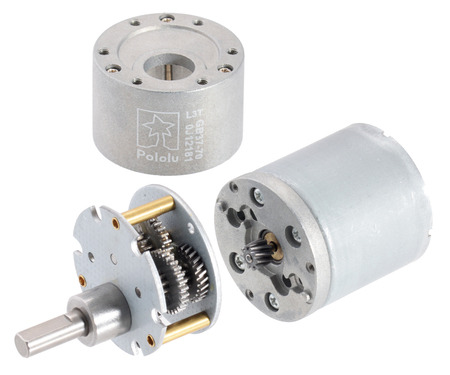

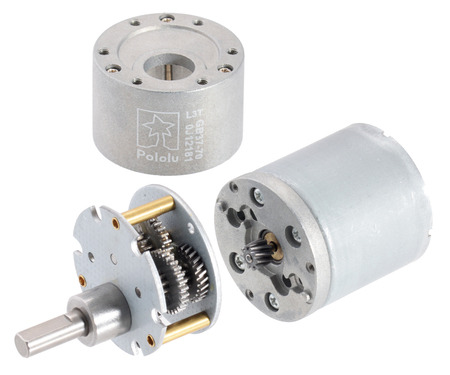

The gearboxes are composed mainly of spur gears, but they feature helical gears for the first stage for reduced noise and improved efficiency:

|

|

37D Gearmotor (Helical Pinion) with the gearbox removed showing the helical pinion gear and first mating gear.

|

|---|

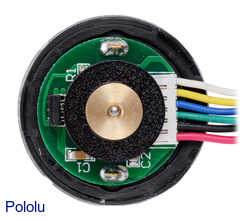

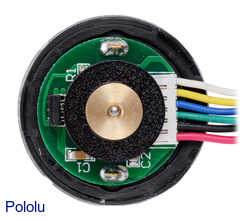

On units with encoders, the encoder portion is protected by a black plastic end cap:

The end cap is easily removable if you need to access the encoder or want to slightly reduce the overall gearmotor size, but there is a little bit of base plastic that will remain, as shown in the pictures below:

Details for item #4691

This gearmotor is a powerful 24V brushed DC motor with a 18.75:1 metal gearbox and an integrated quadrature encoder that provides a resolution of 64 counts per revolution of the motor shaft, which corresponds to 1920 counts per revolution of the gearbox’s output shaft. The gearbox is composed mainly of spur gears, but it features helical gears for the first stage for reduced noise and improved efficiency. These units have a 16 mm-long, 6 mm-diameter D-shaped output shaft. This gearmotor is also available without an encoder.

Key specifications:

| voltage | no-load performance | stall extrapolation |

|---|

| 24 V |

530 RPM, 100 mA |

9.5 kg⋅cm (130 oz⋅in), 3 A |

Exact gear ratio: 25×30×3010×10×12=18.75:125×30×3010×10×12=18.75:1

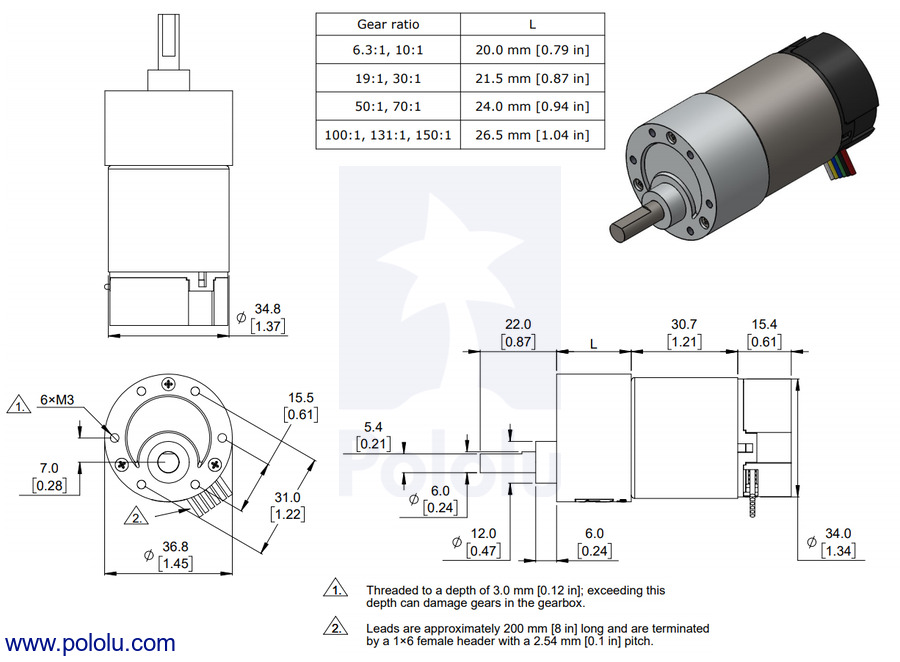

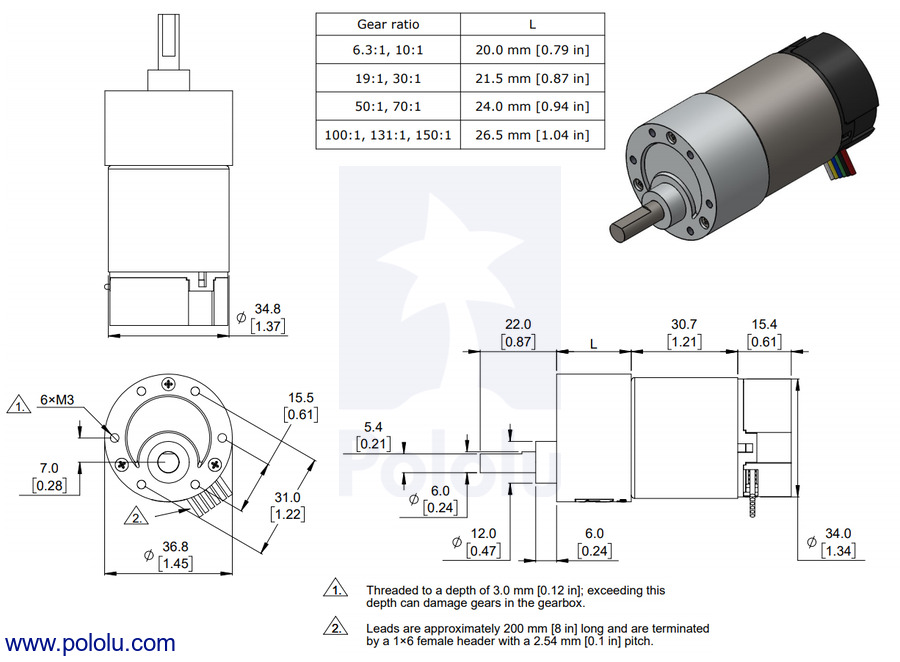

Dimensions

|

|

Dimensions of the 37D metal gearmotors with 64 CPR encoders. Units are mm over [inches].

|

|---|

This diagram is also available as a downloadable PDF (459k pdf).

Warning: Do not screw too far into the mounting holes as the screws can hit the gears. We recommend screwing no more than 3mm (0.12″) into the screw hole.

|

|

37D mm metal gearmotor with 64 CPR encoder (with end cap removed).

|

|---|

Using the Encoder

A two-channel Hall effect encoder is used to sense the rotation of a magnetic disk on a rear protrusion of the motor shaft. The quadrature encoder provides a resolution of 64 counts per revolution of the motor shaft when counting both edges of both channels. To compute the counts per revolution of the gearbox output, multiply the gear ratio by 64. The motor/encoder has six color-coded, 8″ (20 cm) leads terminated by a 1×6 female header with a 0.1″ pitch, as shown in the main product picture. This header works with standard 0.1″ male headers and our male jumper and precrimped wires. If this header is not convenient for your application, you can pull the crimped wires out of the header or cut the header off. The following table describes the wire functions:

| Color | Function |

|---|

| Red |

motor power (connects to one motor terminal) |

| Black |

motor power (connects to the other motor terminal) |

| Green |

encoder GND |

| Blue |

encoder Vcc (3.5 – 20 V) |

| Yellow |

encoder A output |

| White |

encoder B output |

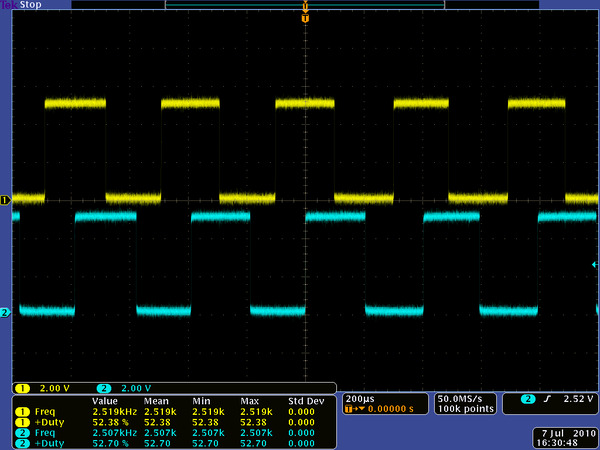

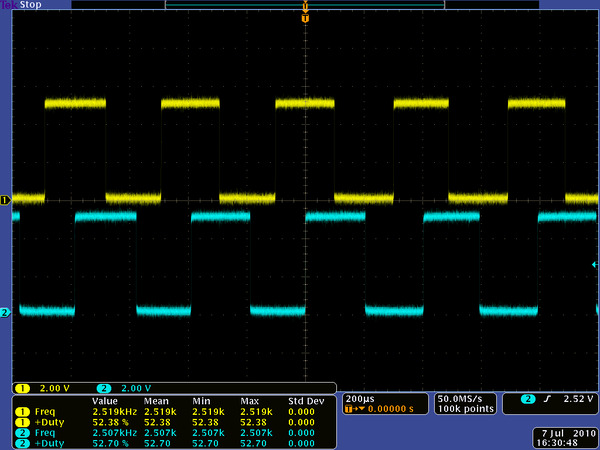

The Hall sensor requires an input voltage, Vcc, between 3.5 and 20 V and draws a maximum of 10 mA. The A and B outputs are square waves from 0 V to Vcc approximately 90° out of phase. The frequency of the transitions tells you the speed of the motor, and the order of the transitions tells you the direction. The following oscilloscope capture shows the A and B (yellow and white) encoder outputs using a 12 V motor at 12 V and a Hall sensor Vcc of 5 V:

|

|

Encoder A and B outputs for 37D mm metal gearmotor with 64 CPR encoder (12V motor running at 12 V).

|

|---|

Dimensions

| Size: |

37D × 68L mm1 |

|---|

| Weight: |

200 g |

|---|

| Shaft diameter: |

6 mm2 |

|---|

General specifications

| Gear ratio: |

18.75:1 |

|---|

| No-load speed @ 24V: |

530 rpm |

|---|

| No-load current @ 24V: |

0.1 A |

|---|

| Stall current @ 24V: |

3 A3 |

|---|

| Stall torque @ 24V: |

9.5 kg·cm3 |

|---|

| Max output power @ 24V: |

13 W |

|---|

| No-load speed @ 12V: |

270 rpm4 |

|---|

| No-load current @ 12V: |

0.08 A4 |

|---|

| Stall current @ 12V: |

1.7 A4 |

|---|

| Stall torque @ 12V: |

5.2 kg·cm4 |

|---|

| Motor type: |

24V |

|---|

Performance at maximum efficiency

| Max efficiency @ 24V: |

52 % |

|---|

| Speed at max efficiency: |

450 rpm |

|---|

| Torque at max efficiency: |

1.3 kg·cm |

|---|

| Current at max efficiency: |

0.49 A |

|---|

| Output power at max efficiency: |

6.1 W |

|---|

General specifications

| Lead length: |

20 cm5 |

|---|

| Encoders?: |

Y |

|---|

| Encoder resolution: |

64 CPR |

|---|

Notes:

- 1

- Length measurement is from gearbox face plate to back of encoder cap (it does not include the output shaft). See dimension diagram for details.

- 2

- D shaft.

- 3

- Stalling is likely to damage the gearmotor. Stall parameters come from a theoretical extrapolation of performance at loads far from stall. As the motor heats up, as happens as it approaches an actual stall, the stall torque and current decrease.

- 4

- This motor will run at 12 V but is intended for operation at 24 V.

- 5

- May vary by a few centimeters.